75% of Amazon Runs on Robots

Ever wondered how that Amazon package arrives on your doorstep with remarkable speed? Clicking "buy" triggers a sophisticated, high-tech chain reaction inside Amazon's vast fulfillment centers, revealing an intricate dance between human workers and cutting-edge robotics designed to meet staggering demand.

"We deliver billions of packages every year, and technology plays a key part behind that," says Tye Brady, Chief Technologist for Robotics at Amazon.

Far from just assisting, robots are now central to the operation. Brady explained that automation is deeply integrated into the process.

"In fact, 75 percent of all the packages that are delivered come through our robotics and automation systems," Brady stated.

Amazon utilizes innovation hubs, including facilities in Texas, as crucial testing grounds for deploying new robotic systems. These aren't just automated arms replacing humans; they are designed from the ground up to collaborate with people. The goal, according to Brady, is clear: "I aim to eliminate the menial, the mundane, and the repetitive."

This focus on human-robot collaboration is yielding significant results in both efficiency and worker well-being. Brady shared compelling data indicating that robotics-enabled facilities process packages 25 percent faster, reduce operational costs by 25 percent, and boast a 30 percent lower rate of recordable safety incidents.

"It really gets to the heart of allowing our machines to enable more productivity, more creativity, more intelligence from our amazing frontline employees," Brady emphasized.

Amazon’s Physical AI

Amazon is pioneering what Brady terms "Physical AI." This involves managing a complex, controlled chaos of autonomous robots moving goods throughout the facility, all navigating safely alongside their human colleagues.

"Think of an air traffic controller that are controlling thousands of robots at the same time," Brady illustrated. "Allowing the bots to move goods at will to facilitate the jobs of our employees."

And the technology isn't standing still. Brady noted that these robots are continually becoming smarter, faster, and more adept. The future involves even greater automation capabilities.

"We want to be able to pick up objects, identify those objects, and pack those objects automatically," he said.

This powerful fusion of human expertise and advancing artificial intelligence is constantly reshaping the landscape of logistics, driving the speed and efficiency that defines Amazon's delivery promise.

Looking to hire automation or robotics talent?

We help companies find top-tier engineers, integrators, and developers — and provide upskilling support where needed. Contact us to build your team.

Macy’s newest customer fulfillment and store replenishment center is a highly automated, state-of-the-art facility and the company’s largest and most advanced.

World’s largest food company is cutting 16,000 jobs due partly to automation.

Ekol Logistik, a Turkish 3PL, will build an automated mini-load warehouse on the outskirts of Istanbul.

The automation technology allows products to be retrieved from a 125,000-square-foot grid and delivered directly to employees, improving fulfillment speed, accuracy and efficiency.

The new facility will feature a cutting-edge case-picking and pallet-building system.

The offer builds on Amazon fulfillment service for merchants on other sales channels, including eBay, Etsy, Temu and TikTok Shop.

Spend 24 hours inside a DHL warehouse and experience how robotics is transforming its logistics.

LAPP USA partnered with Corvus Robotics to solve a long-standing supply chain challenge:.

After invested billions of dollars into automated e-commerce Kroger will now depend on its stores for digital growth.

More retailers are improving their 'Click and Collect' services, with one new trial using mini robots to speed up the process.

Walmart is now deploying automated packaging technology across multiple centers in Pennsylvania, Illinois, Texas, and California.

96% of Target’s online orders is fulfilled by its stores rather than warehouses

In our research with SMEs, we have uncovered strategies that can make automation feasible, even for businesses with lean budgets.

This new development signals a clear step forward in solving one of the most pressing challenges in warehouse automation today: space and deployment efficiency.

Wayfair UK is looking to sublet part—or potentially all—of its 1.068 million ft² distribution centre at Magna Park Lutterworth, one of the UK’s most strategically located logistics hubs.

Over the past decade, the number of industrial robots on China’s factory floors has increased more than six times to over 1.7 million,

A newly launched robotic fulfillment center in Oberhausen, Germany, is setting a new benchmark for automated grocery logistics in Europe.

Honeywell expressed interest in acquiring the Calgary robotics startup in 2020. Today, Attabotics is in creditor protection.

The new facility brings together four sites into one 47,000m² distribution centre, increasing the company’s storage capacity by 60 per cent.

Inside Sephora’s UK logistics operations and DHL’s deployment of Boston Dynamics robots.

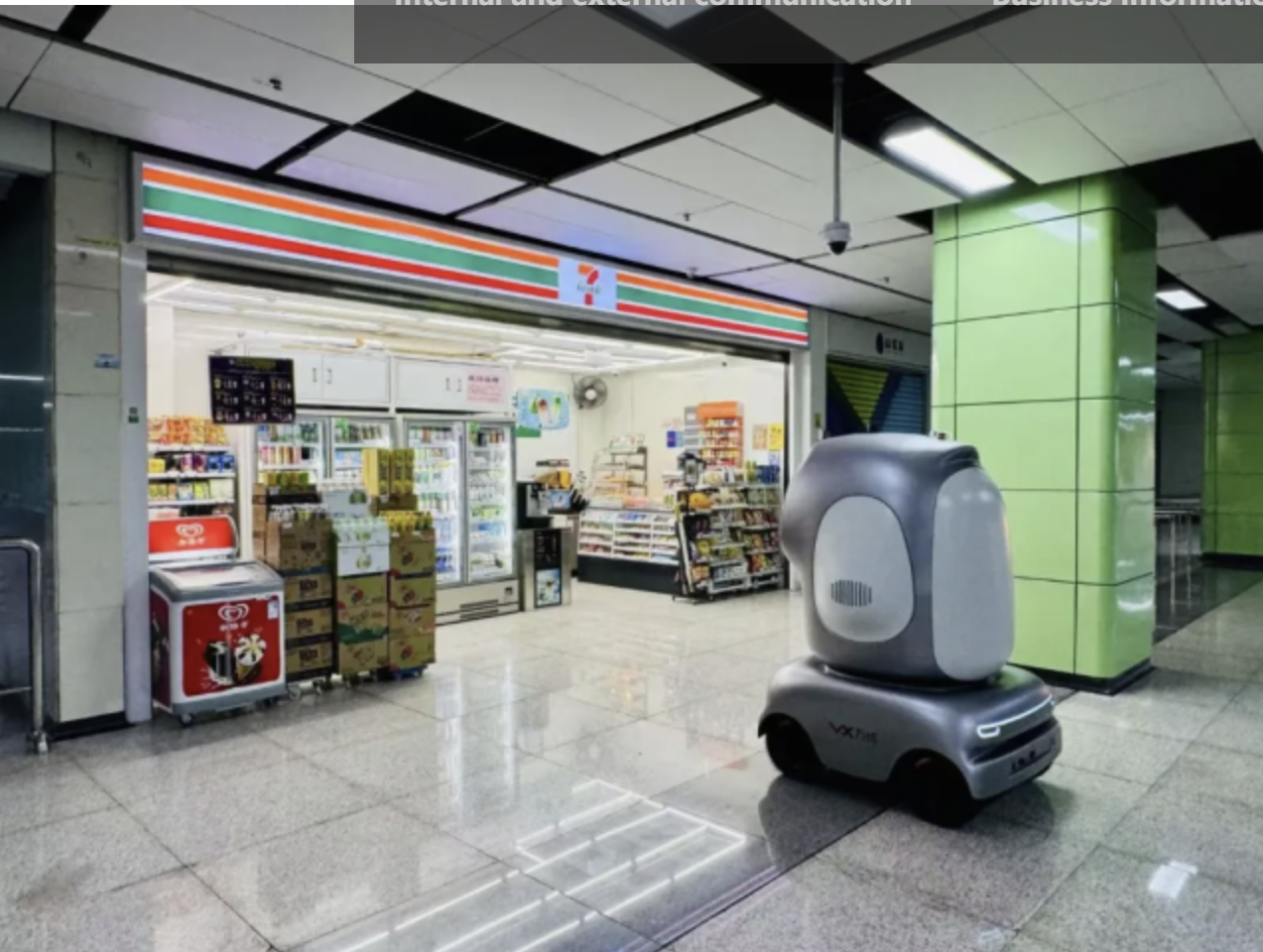

41 autonomous delivery bots have taken over Shenzhen’s subway to keep snacks stocked.

Attabotics filed for insolvency after Export Development Canada sought to enforce security over assets.

Good News for Warehouse Operators: 100% Write-Offs Are Back for Automation Investments

Attabotics Inc., a Calgary-based robotics and automation startup, has filed for bankruptcy protection, according to multiple reports.

Peggy Johnson, CEO of Agility Robotics, discusses how humanoid robots like Digit are transforming logistics and manufacturing. She speaks with Bloomberg Businessweek's Brad Stone about the rapid advances in automation and the next era of robots in the workplace at Bloomberg Tech in San Francisco.

DHL Group has signed a strategic Memorandum of Understanding with Boston Dynamics, a global leader in advanced robotics.

In robotics, dexterity and perception go hand-in-hand, literally!

Host Evan Reiser welcomes Sally Miller, Global Chief Information Officer at DHL Supply Chain.